Focus on The Essentials

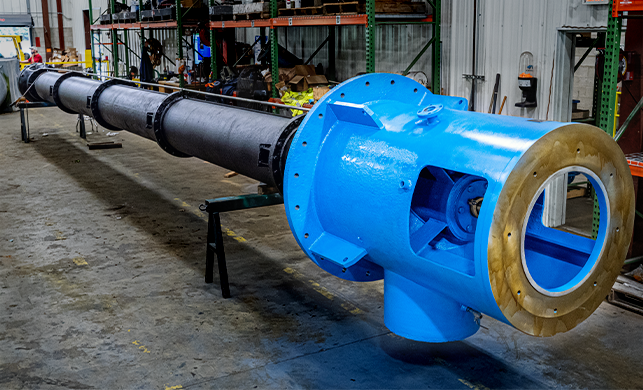

Repairing vertical turbine pumps is a complex process that requires precision and attention to detail. At Southeast Pump, our repair process yields reliable vertical turbine pump repairs because we focus on the essentials: proper alignment and tolerances, material characteristics of the parts, and a balanced impeller. We will expand on these and other important considerations when repairing and rebuilding vertical turbine pumps that will last.

Register Fits and Bearings

In a vertical turbine pump, the register fits are critical components that ensure proper alignment of the pump’s bearings, impeller, and shaft. If the registers are not machined to the proper tolerances, vibration will occur, causing rapid bearing and wear band fraying and eventual failure. To prevent these problems, Southeast Pump increases tolerances beyond manufacturer recommendations for improved reliability. We do not allow the column register fit’s clearance to exceed beyond half of the shaft to bearing clearance.

This ensures the vertical turbine pump will run without impacting the bearings or wear bands should some vibration occur. We safeguard our machined registers, shafts, bearings, and wear bands with state-of-the-art equipment, including CNC horizontal boring mills and lathes. With these rigorous standards and precision tools, vertical turbine pumps repaired in our facility will be precisely aligned and safeguarded against misalignment.

Material Quality of Parts

When selecting materials for wear bands, wear rings, and bearings in a vertical turbine pump, several important considerations must be kept in mind. The material’s ability to withstand the corrosive effects of the fluid being pumped and any abrasive particles present is critical. For example, softer metals such as bronze and brass are often used for wear rings and wear bands when pumping fluids with abrasive particles as they can absorb some of the impact and minimize wear on other components. However, stronger metals such as stainless steel and tungsten carbide may be used in environments with higher temperatures and pressures or when pumping highly corrosive fluids.

In addition to fluid characteristics and the operating environment, mechanical properties such as high strength, low friction, and good wear resistance must also be considered when selecting materials for bearings. It’s important to note that the same material may not be suitable for both bearings and wear rings as they have different wear characteristics and functions. For example, some bearings may be made of bronze, which is softer and more forgiving than materials used for wear rings/bands. This is because bearings are designed to take on the majority of the load and reduce friction, while wear rings absorb the wear from the impeller and casing. Our application and mechanical engineers can help you find the perfect combination of these parts’ materials to suit your vertical turbine pump and the application to maximize your pump’s reliability and performance.

Need Help With a Project?

Our application and mechanical engineers are ready to help!

A Balanced Impeller

Balancing a vertical turbine pump impeller is a critical step in the repair process. When the pump is disassembled for repair, the impeller is often removed from the shaft and inspected. Even minor changes to the impeller’s weight distribution or shape can cause the impeller to vibrate and create excessive wear on the bearings and wear rings which can lead to premature failure. For this reason, we always balance new or used impellers on our state-of-the-art 10,000lb capacity balancing machine when rebuilding a vertical turbine pump. Our process involves balancing the impeller to ISOG 1.0 – a higher that standard tolerance.

As mentioned with our register tolerances, we believe a tight impeller balance tolerance reduces the chances of vibration and stress, and it adds an exceptionally higher degree of reliability. Even as the impeller sustains some damage from everyday wear and tear, it can remain within the standard tolerance longer due our higher balancing standard.

Conclusion

Exceptional repair and rebuild of a vertical turbine pump requires attention to detail and precision. Register fits must be machined to the proper tolerances using bearing clearance as a guide to ensure reliable alignment. The material quality of parts must be considered based on the fluid being pumped and the operating environment. And balancing the impeller is crucial to prevent vibration which result in excessive wear on bearings and wear rings from. At Southeast Pump we advance the ideal of achieving excellence in vertical turbine pump repairs through our precise tolerances, state-of-the-art equipment, and rigorous standards. Our objective is to maximize the operational lifespan of vertical turbine pumps repaired in our facilities. By implementing these rigorous standards, we believe we are on our way to achieving our goal.

Learn more about our cost saving solutions!

Cooling Tower Pump Rebuild