Overview

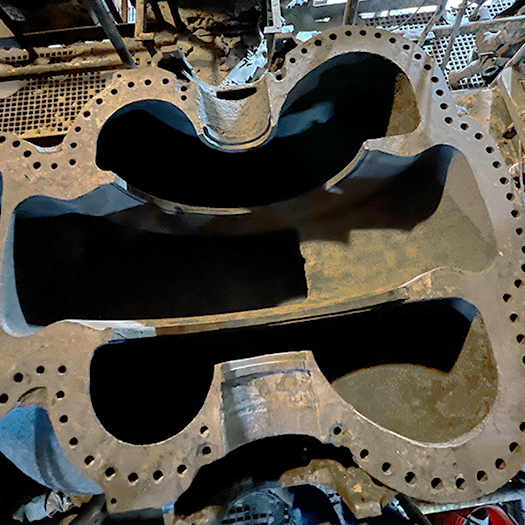

A paper mill in the southeast was experiencing extreme corrosion and erosion on the casing of a Warren 36DLB38 Pump – the heartbeat of their paper machine. A true workhorse pump with over 50 years of operation has led to corrosion and erosion that resulted in leaks and efficiency issues. Since a 2008 inspection, the casing developed holes, and the stuffing box’s grooves had deteriorated making it difficult to find a successful sealing surface for new packing. The mill needed an innovative approach to avoid a costly capital equipment purchase and extended down time. During their annual outage, Southeast Pump Specialist developed and implemented a quick solution to repair the casing and stuffing box within the outage time frame.

Need Help With a Project?

Solution

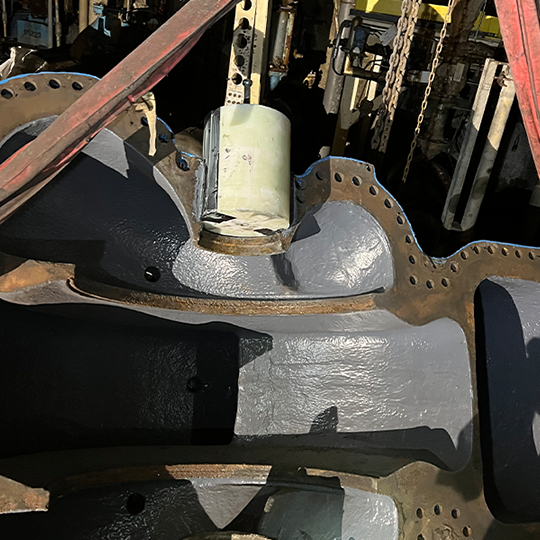

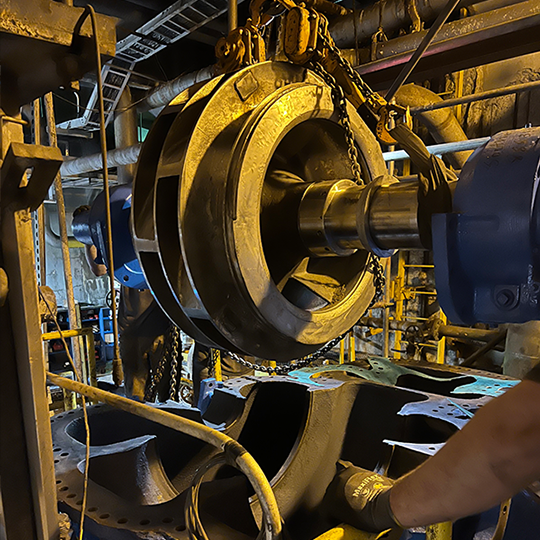

Southeast Pump Repair experts suggested sandblasting the casing to bare metal and apply the A.W. Chesterton ARC 858 as a base coat to fill in the large crevices and pitting with a dual layer of SD4i coating on top to ensure longer performance and wear pattern insights during future disassembly. Our Services Team set up our mobile sandblasting unit on site to sandblast both halves to bare metal to create an ideal surface for ARC coating adhesion, and they created a template from PTFE billet of the same size as the original OD of the stuffing boxes. This billet provided our team the final OD with straight edges. In addition to the casing work, we also removed the rotating element, installed new bearings in our SKF certified clean room, and balanced it to ISO G1.0. During the next outage, our customer is planning to examine the wear patterns and apply additional coating to reinforce areas with greater wear.

Results

The project was completed within 10 days with the pump running perfectly without any leakage. The maintenance planner was extremely impressed with the quality and efficiency of the Southeast Pump team. The maintenance manager even went so far as to say that this project is one he is the proudest of during his time with this paper mill. The pump continues to run to this day and the leaders at the papermill are ecstatic about how well the pump is running.

Cost Savings

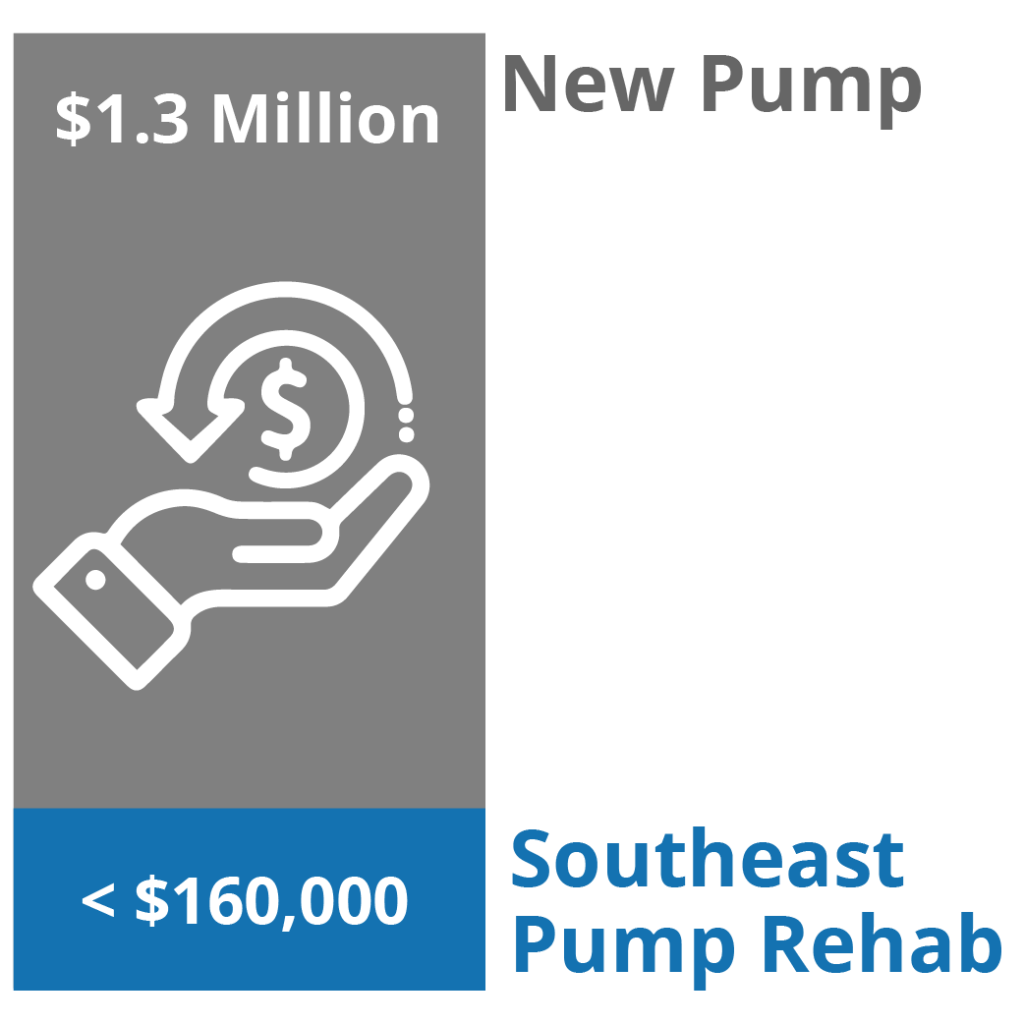

The project for this paper mill saved them potentially over $1 Million when they were staring at purchasing a new pump. A new pump would not only bring the cost of purchasing capital equipment, but also piping, base, and parts changes. Hiring the Southeast Pump Specialist team to develop and apply practical solutions for the complex problem spared the paper mill from incurring a steep cost to resolve the challenge. For example, the cost of a new fan pump for their paper machine was in the range of $1.3 million after accounting for all system changes and equipment. Southeast Pump quoted and invoiced the job for no more than $160,000 – more than $1,000,000 in savings!

Learn more about our cost saving solutions!

Improved Paper Stock Pump Reliability