What kind of centrifugal pump do you need? This is a question best answered by your pump professional and therefore this article is meant to give you a rough guide and big picture view of the types of pumps there are in the industrial world.

Let us take a loser look at some of the types of industrial pumps that are used in the various industries across the world.

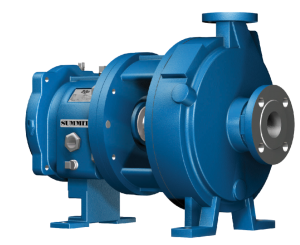

Close Coupled

Close Coupled

These pumps are supplied so close to the motor where the motor shaft extends into the pump and functions as the pump shaft. These are compact and simple pumps and typically operate under 25 horsepower. View our offerings from Summit Close Coupled Pumps

Cradle Mounted

These are pumps which have separate drive motors connected by a coupling. These pumps are often separated from the motor a larger distance than Close Coupled pumps and require a coupling to connect the pump and motor shafts together.

Vertical Inline

These pumps are compact and take up less space because, like the name suggests, they are situated vertically. Vertical Inline Pumps are ideal for environments and applications where space is limited.

Split Case

These pumps are typically used for higher flows. Within the pump’s intake there are two inlets which divide the product evenly to the single or double impeller(s) and disperse the product at a high rate. Bearings are housed on both ends of the shaft and therefore packing or mechanical seals will be needed on both ends to protect the bearings. Split Case pumps are often used for fire water applications, though there are many other applications it can be used for.

Vertical Turbine

The Vertical Turbine pump is another pump that is used for high flow rates. It has a vertical line shaft driven impeller housed in bowl assemblies. These pumps can produce flows from 100 gallons per minute (gpm) up to over 100,000 gpm. The number of bowl assemblies on a vertical turbine directly affects the amount of pressure it can achieve. The more bowl assemblies (or stages) there are, the more pressure that can be generated. Typically, they are lowered into sumps or wells to bring water near or to the surface. Most vertical turbines are sued for drinking water, irrigation water, or cooling water for power plants.

ANSI

The workhorse for the chemical industry is the ANSI pump. ANSI stands for American National Standards Institute. There is a specification that details the construction and design of these standardized pumps which are interchangeable between manufacturers. This means you can change brand X pump for brand Y pump, and it will fit into your pipping. There are many different styles and applications that ANSI pumps can help resolve including: Surry Pumps, Low Flow Pumps, Self-Priming Pumps, Heavy Duty Pumps for Food Process, Pulp, and Paper Pumps, and more. In general, They have construction features specific for handling chemicals such as the ability for a wide range of mechanical seals, easy access to the mechanical seals and bearings, and overall a heavy-duty rugged design available in a wide range of corrosion resistant materials.

Magnetic Drive

For very aggressive, hazardous, or toxic chemicals there is an option to eliminate seals altogether. Magnetic Drive pumps are sealless pumps. An outer magnet driven by a motor drives an inner magnet through a containment shell which drive the impeller to pump. There are no rotating seals, but the internal bearings are lubricated by the product that is being pumped. Keep in mind that if your product has a fair amount of solids, this pump would not be a good fit. Magnetic Drive pumps are an excellent solution for very aggressive, hazardous, or toxic chemicals that you would not want to leak.

Sumps

Earlier I discussed how a vertical Turbine pump can pull water out of a sump, however they are mainly used for pulling water that has very little solids in the product (drinking water, irrigation water, etc.) There are a few design options for sump pumps: Vertical Cantilever, Self-Priming, and Submersibles. These pumps allow flexibility with your engineers in how you want to set up your sump. I highly recommend Toyo Hevvy Pumps for their reliability to be able to withstand the harshest of conditions.

Vertical Cantilever

You might recognize the name from the previous section. Vertical Cantilever Pumps are similar to vertical turbine pumps, but instead of having the product run up through the shaft, the impellor is submerged in the in the product while all bearings, mechanical seals, and bushings are outside of the product. The motor sits on top of the floor level.

Self-Priming

This pump lifts the water out of the pit while the pump sits on the floor level above. With These pumps it is important to ensure that the inlet and discharge pipping is air tight and there is water present inside the pump before turning on the pump.

There are many unique and different styles of pumps within the types of pumps mentioned here and the professionals at Southeast Pump Specialist are here to help you find the perfect pump for your application.