If you buy or use industrial or municipal pumps, you need to be able to read a pump curve. A pump curve is a detailed spreadsheet of a pump’s performance at specific intervals, the use of which helps you determine the configuration and type of pump you need for your application. It’s like looking at the product details of a light bulb in comparison to your electrical socket and lighting needs. We are going to look at the various intervals and measurements that you need to consider in order to make the best decision for your application.

Overview

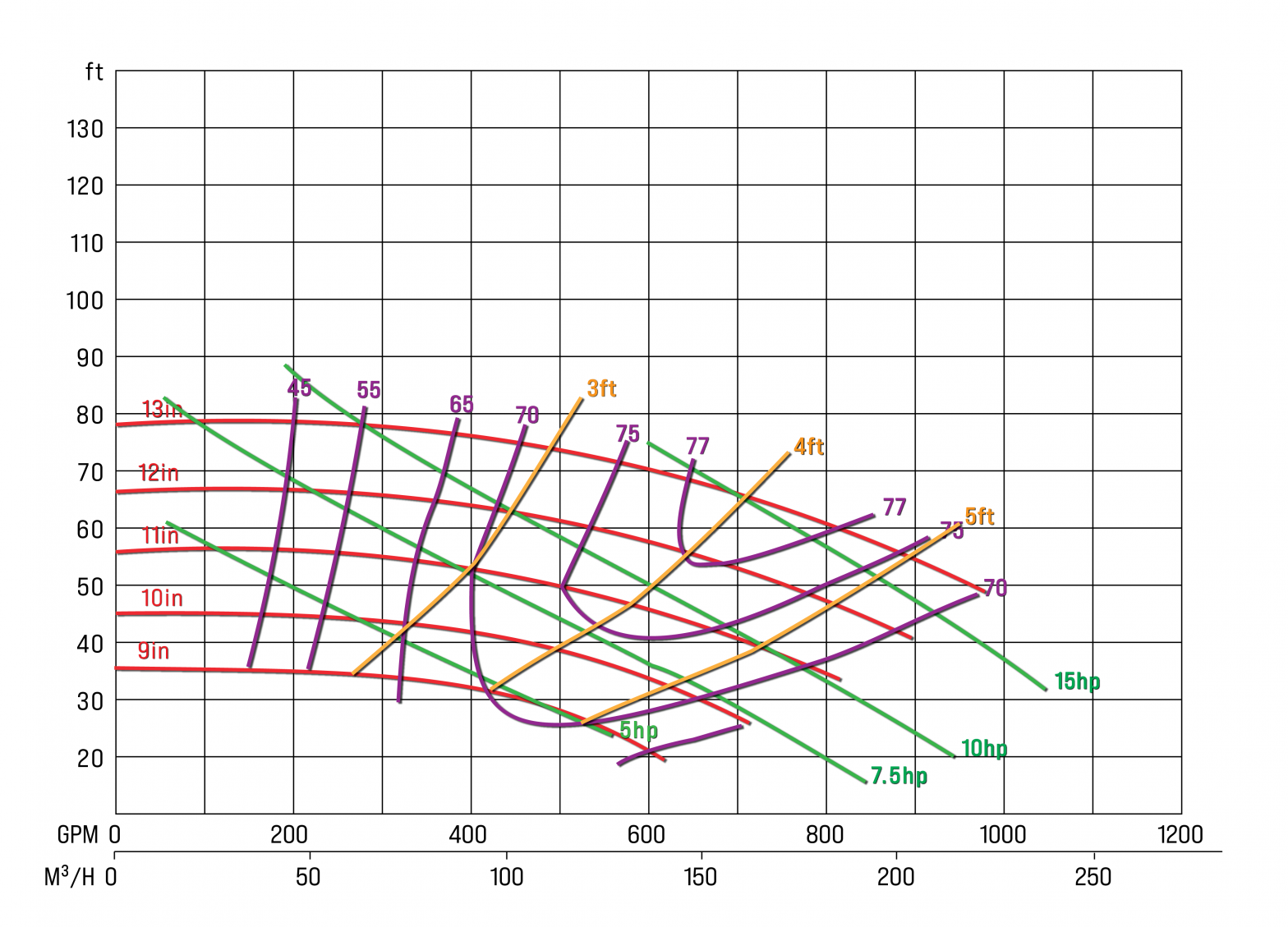

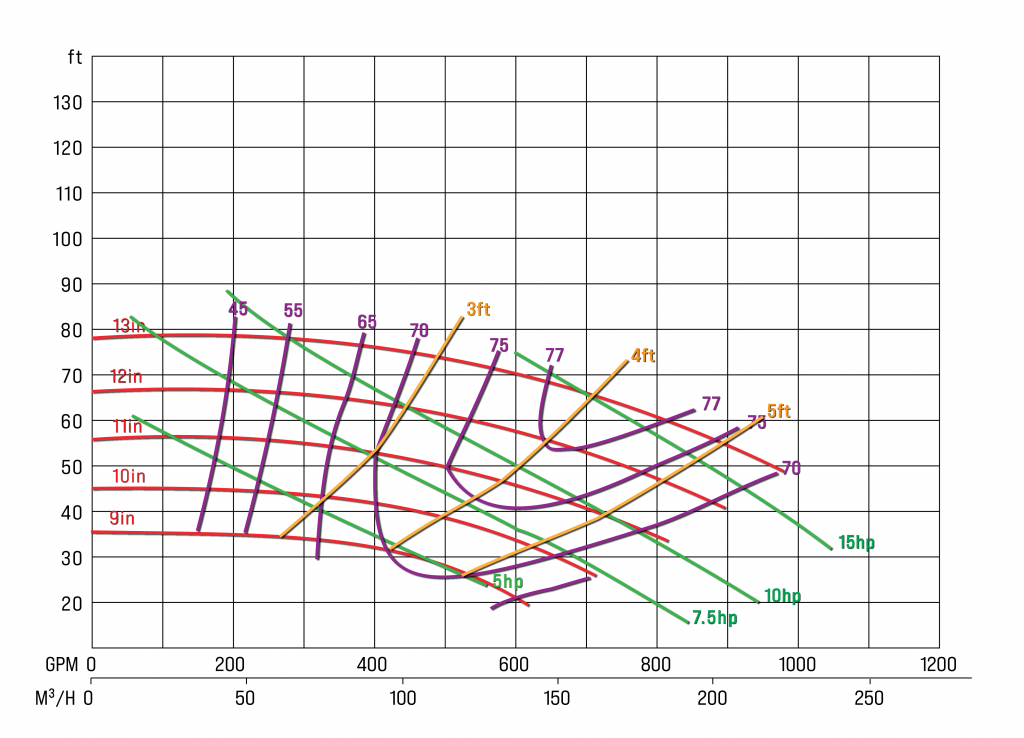

The graph shown here is where a pump curve is usually charted. Keep in mind that not all manufacturer’s pump curves will look the same, but they will follow these general principals. It is best to start by defining what the X and Y axis are measuring:

The X Axis (Horizontal Line) gives the Flow Rate. On this graph, it’s recorded as Gallons Per Minute (GPM) and Cubic Meters per Hour (M³/H). The Y Axis (Vertical Line) gives the discharge pressure measured in Feet of Head – how far the fluid will travel given ZERO friction losses.

As we take a closer look at pump curves, it is important to note that the viscosity of the fluid will change the curve entirely. The viscosity of liquids changes when the temperature changes. For this curve, I am using room temperature water as the fluid being pumped. For pumping purposes, you want to measure the Dynamic Viscosity of the fluid since it is moving. At 70°, water has a Dynamic Viscosity of 975 mPa-s (Millipascals/second), and that is the viscosity of the fluid outlined in the Pump Curve I am showing today. The easy part is done. Now, we dive a little deeper into what all the different lines in the middle of chart are.

Efficiency

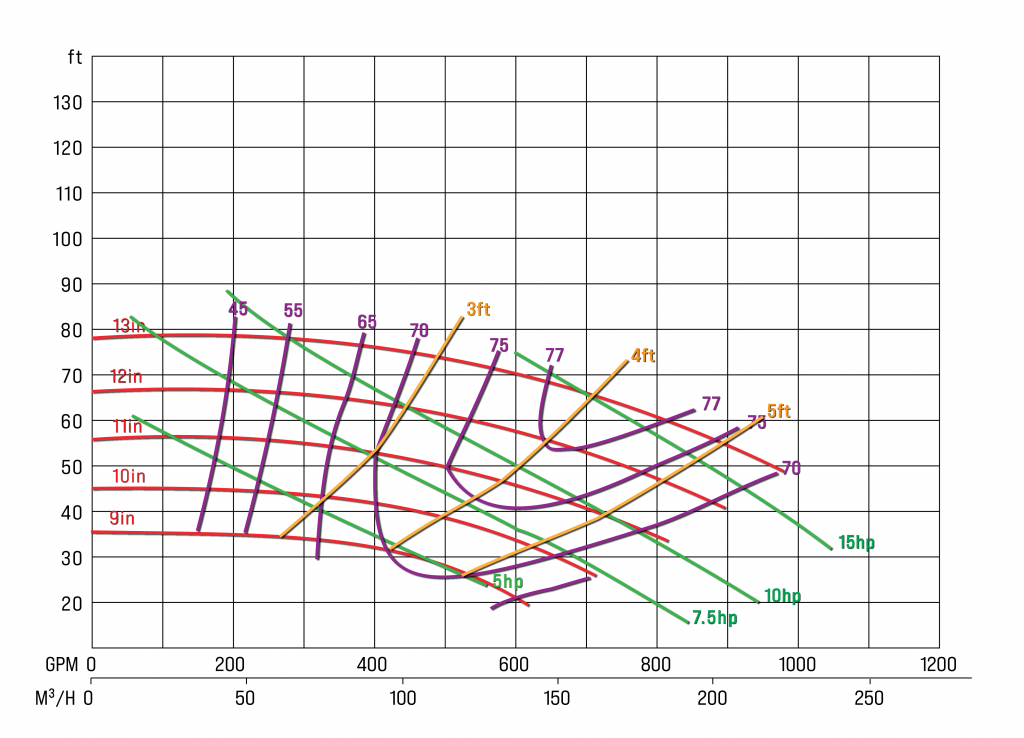

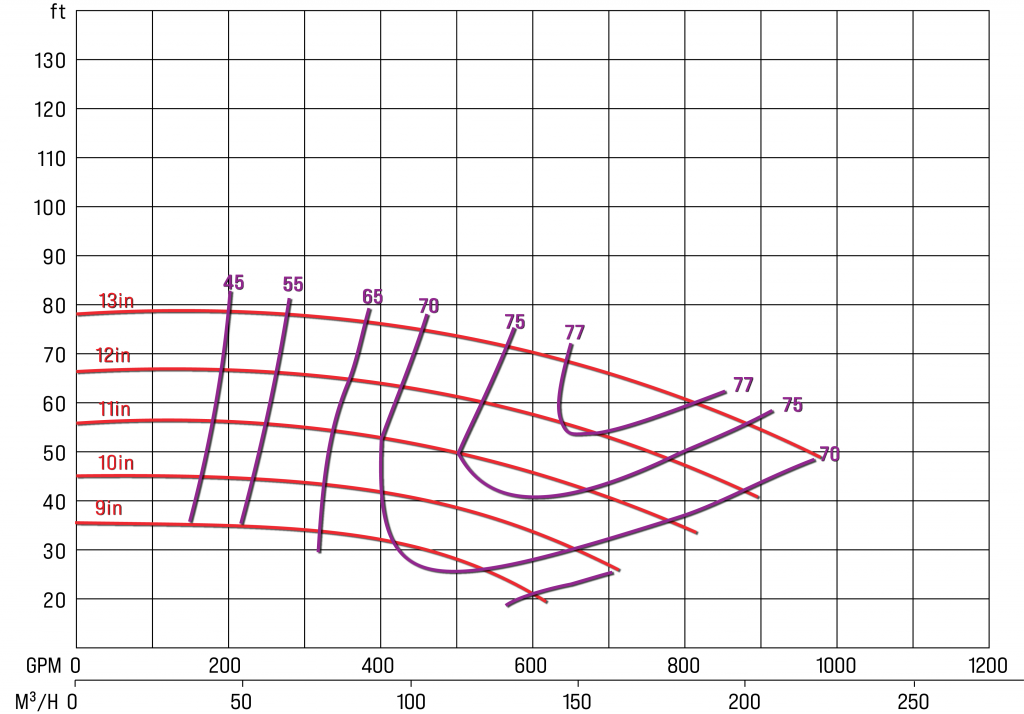

When looking at a Pump Curve, you always want to find the conditions under which the pump will operate at its best. In the “Efficiency Graph,” you can see several curves with numbers labeling, in percentages, where the pump’s efficiency will be at the various flow rates. When you look at this specific pump’s efficiency curve in the graph, you want to look at the area in between the curve labeled 77, because that is where it will perform its best.

Based on the efficiency curves in the efficiency graph, you can expect this particular pump to be able to generate ~650–850 GPM at ~55–70 Ft of Head at its best. However, this does not mean that pump can only operate within those parameters. Indeed, this pump can operate between the lowest efficiency, 45 percent, to right-most side of the 70 percent curve without any vibration caused by cavitation.

If you want to pump ~ 950 GPM at ~48 ft. head, then this pump will work well for you at about 70% efficiency. It is when you deviate outside of the represented curves that you run into problems. If you want to pump 1000 GPM at any head, then you will need to seek a different pump, because the pump will constantly cavitate and fail quickly. It all boils down to what your application needs are; reading the efficiency curves is the best place to start when checking a pump curve.

Horsepower Requirements

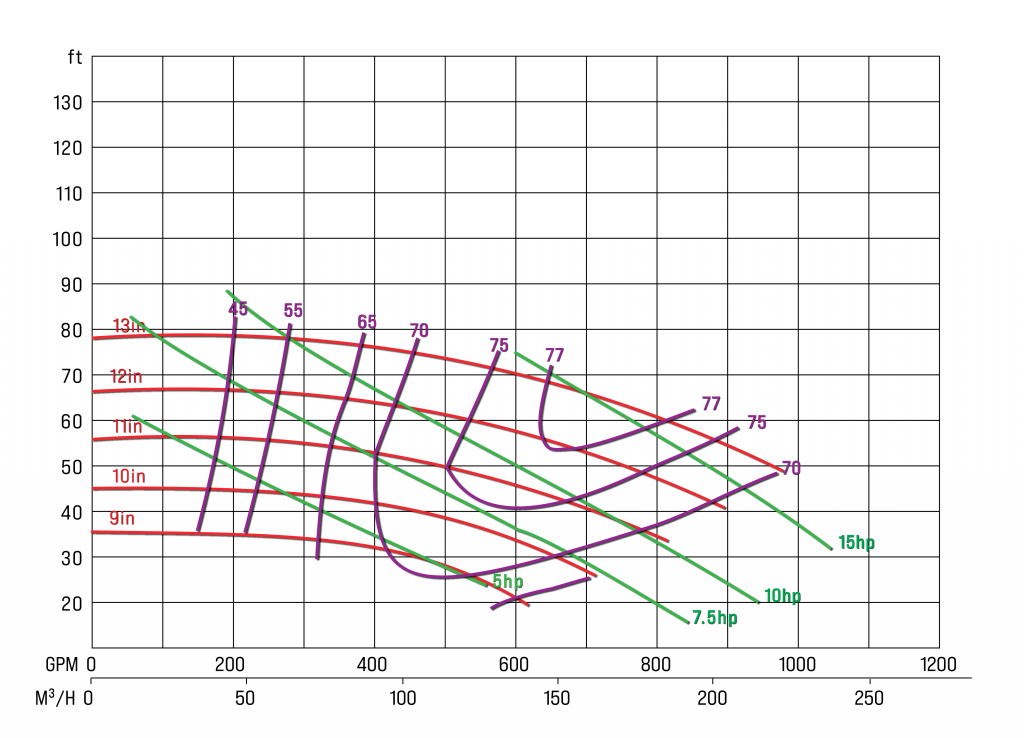

The horsepower requirements for the flow you want to achieve combined with the impeller diameter is laid out in the associated chart. The horsepower curve is outlined in green. It is recommended that the motor selected have 1.2x more horsepower than is required for the flow rate of the application.

For example, if your application needs 400gpm at a rate of 52 ft of head, then you will want to bump up to a 10hp motor. This protects you motor from failing when loads on the pump increase unintentionally. However, a 10hp motor without a Variable Frequency Drive (VFD) exceeds the power necessary to pump 400gpm at 52 ft of head, and the impeller will need to be trimmed to a little less than 11in for the pump to operate within the application’s parameters.

When the horsepower, impeller size, and efficiency curves are combined it will give you a good idea what size and type of impeller and motor you will need to pump your product and how efficient the pump will be at pumping that product. To take the example from before: if you want to pump 400gpm at 52 ft of head, then your pump’s specs will be the following:

- ~ 10.8in size impeller

- 10 horsepower motor

- Pump Efficiency ~ 70%

Net Positive Suction Head (NPSH)

The final curve that you will need to consider when examining a pump’s curve is the Net Positive Suction Head. NPSH is defined in two ways: NPSHa and NPSHr. NPSHa is the liquid pressure available for the pump at the inlet right before the water enters the impeller.

NPSHr is the liquid pressure required for the pump in order to prevent cavitation. Therefore, this is an important curve to consider, because if unchecked, the pump could have significant cavitation and fail prematurely. The NPSH curves outlined in this graph (yellow) show the NPSHr of this particular pump. Before selecting a pump, you will need to make sure that your NPSHa is higher that the NPSHr. Let us look at our example from before: An application that requires 400gpm at 52 ft of head will need 4 feet of NPSHa. Even though the NPSHr curve of 3ft is intersecting right where our application parameters are intersecting, it is best practice to ensure that you have as much as 1-2ft more NPSHa to avoid cavitation.

Pump curves can be difficult to decipher at first glance, but they contain extremely important information to consider before purchasing a pump for your application. No matter how much or how little you are pumping, remember to stay within the highest efficiency possible. You might be able to trim the impellor down if it helps you stay within your application’s parameters, and if your requirements come too close to exceeding the horsepower of your motor, then be sure to get the next size up of motor so your motor does not fail when the pump handles more strenuous loads. Finally, be sure to measure your NPSHa and procure a pump whose NPSHr is within what you have available by at least 1-2 feet.