The pump impeller is the rotating component in the pump that directly transfers the energy from the motor into the fluid being pumped. There are three types of impellers used in centrifugal pumps: closed, semi-open, and open. Each type offers different benefits and disadvantages, and choosing the type you need for your application depends on the fluid being pumped, the NPSHa, and the head pressure that is needed. Taking these into account, it is also important to note that the different impellers will impact the pump curve and change the BEP (best efficiency point). For more about a pump’s BEP and reading pump curves check out our pump curves post.

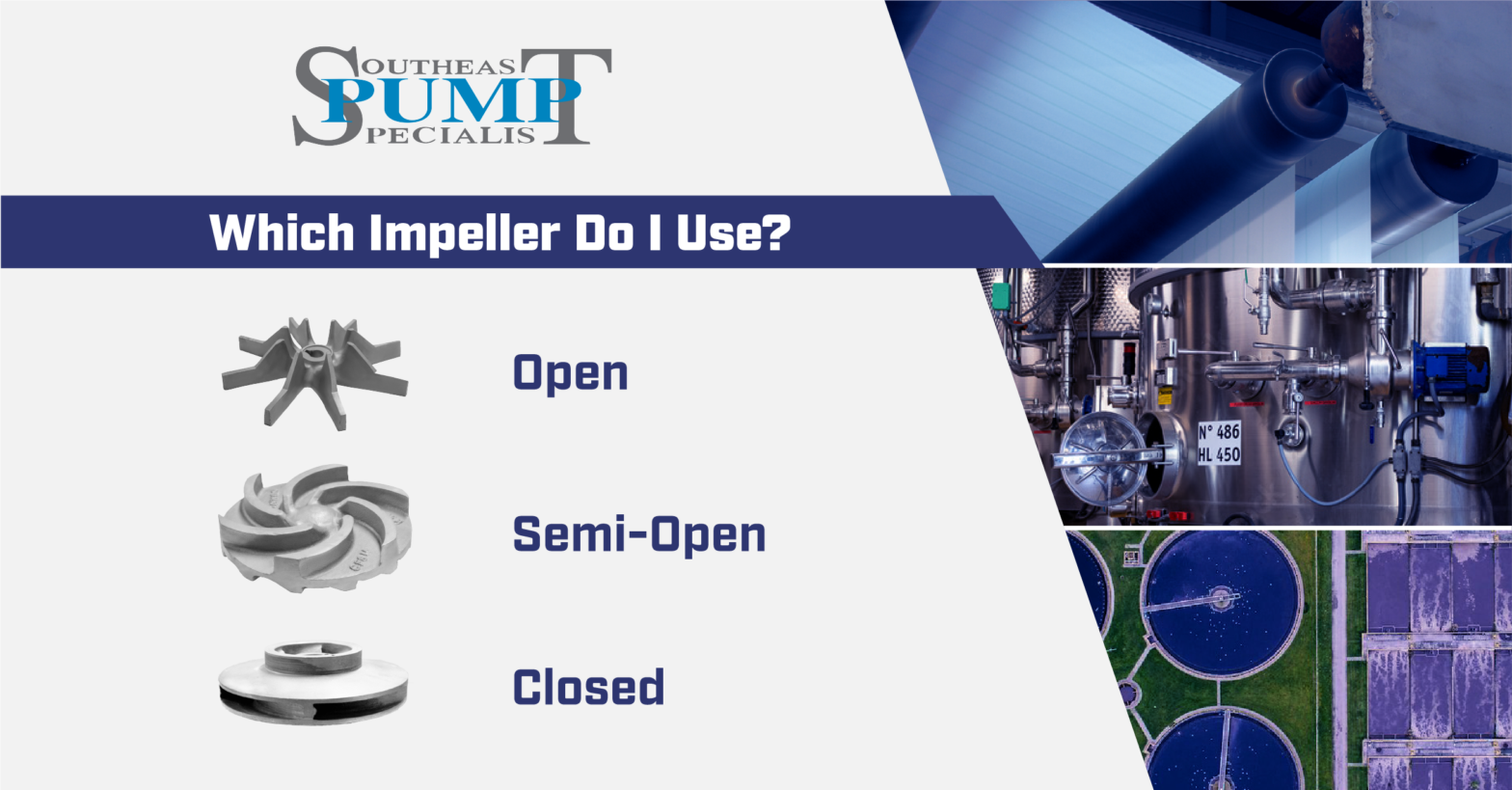

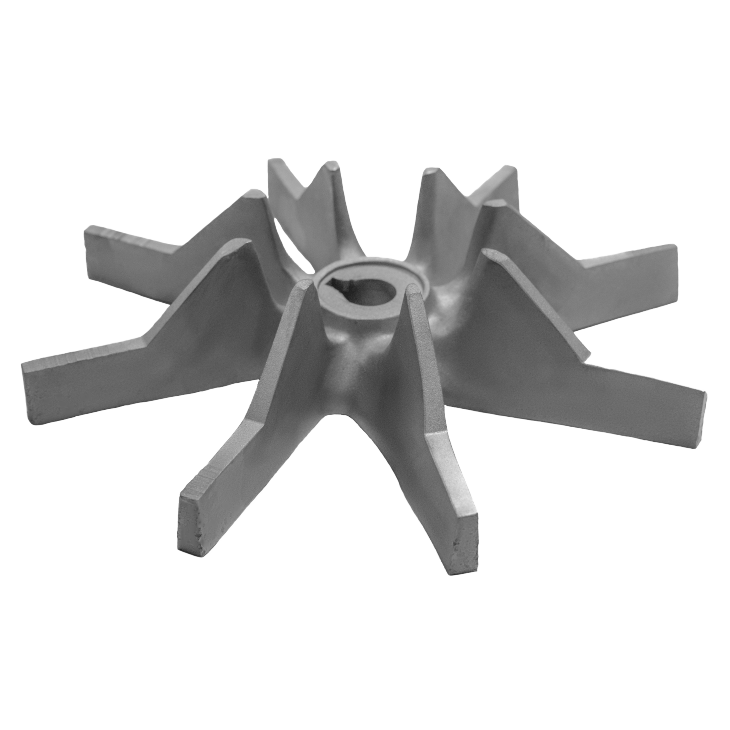

Open Impellers

An open impeller has vanes that are attached to a central hub, but they are not enclosed on all sides. This design allows fluid to flow freely through the impeller, but it can also result in some loss of efficiency due to the fluid being able to bypass the vanes. Accordingly, open impellers are used in pumps that handle liquids with low viscosity, such as water, or in situations where the pump needs to be able to pass solids or other large particles through it. In many cases, open impellers are seen in paper stock applications due to low viscosity, but higher particle density. The open design allows thick paper stock to get through the impeller and maintain the flow without damaging or impeding the impeller.

Closed Impellers

A closed impeller has vanes that are completely enclosed by surrounding rings or “back plate.” This design helps to prevent fluid from bypassing the vanes, which can result in improved efficiency and higher pressure output. Furthermore, closed impellers are often used in pumps that are handling liquids with high viscosity, such as oils, or in situations where high pressure is required. In our experience, we recommend closed impellers in water boosting applications seen in water treatment and wastewater treatment facilities

Semi-Open Impellers

There are also semi-open impellers, which have partially enclosed vanes, and shrouded impellers, which have a shroud or cover over the vanes to help direct and guide the flow of fluid. Keeping this in mind, the semi-open impeller design can offer a balance between the performance of open and closed impellers, and, depending on the specific needs of the application, can offer a, best of both worlds, option for those that are caught deciding between the two aforementioned options.

Furthermore, we recommend consulting with our pump experts and mechanical engineers to determine the best impeller design for your particular application. We will consider the specific characteristics of the application, the required performance of the pump, and your system performance to recommend the most suitable impeller design.

Need Pump Experts On Site?

We have NCCER certified millwrights ready to come on site and inspect, install, repair, and perform routine maintenance on all your rotating equipment.