What Is a Pump Curve?

If you buy or use industrial or municipal pumps, you need to know how to read a pump curve. A pump curve displays a pump’s performance at specific flow rates and pressures, helping you determine the best pump configuration for your application. It’s similar to checking the specifications of a light bulb to ensure it fits your socket and lighting needs.

Basic Pump Curve Terminology

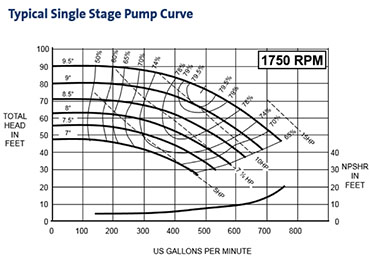

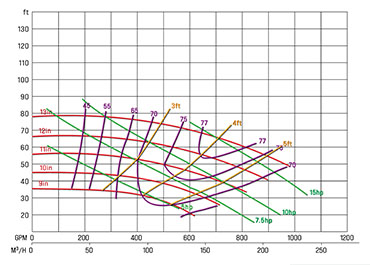

Pump curves usually appear as a graph. The X-axis represents flow rate (in GPM or M³/H), and the Y-axis shows discharge pressure (measured in feet of head). This graph provides vital information about how a pump performs at various conditions.

What Does a Pump Curve Tell You?

When examining a pump curve, focus on the efficiency curve, which shows the areas where the pump operates most efficiently at various flow rates. It is best practice to identify where the Best Efficiency Point (BEP) is on the curve and configure your pump accordingly. If your application requirements put the selected pump below ~70-80% efficiency, you may need to look for a different size pump that will give you a higher efficiency. The energy that your pump uses should always be considered when estimating pump cost because, generally, 85% of a pump’s purchase cost will be from the energy it consumes.

Understanding NPSHa and NPSHr to Avoid Cavitation

To avoid cavitation, ensure that your pump’s Net Positive Suction Head Available (NPSHa) exceeds the NPSH Required (NPSHr). NPSHa is the available suction pressure before the liquid enters the inlet and impeller, and NPSHr is the minimum pressure needed to prevent cavitation. For example, if your application needs 400 GPM at 52 ft of head, maintain an NPSHa that exceeds the NPSHr curve by at least 1-2 feet to avoid cavitation.

Horse Power and Pump Selection

When selecting a motor, consider the pump’s horsepower requirements based on the flow and head. For instance, if your application requires 400 GPM at 52 ft of head, choose a 10 horsepower motor to handle increased load demands. Opt for a motor with 1.2x the required horsepower to ensure reliable performance and prevent motor failure.

Final Thoughts

A clear understanding of pump curves, NPSH, and horsepower requirements will help you select the right pump for your system. Check the efficiency curves to find the optimal operating range of horsepower, impeller size, and NPSH required to ensure you make the right choice. With the right pump selection, you’ll maximize efficiency, reduce maintenance costs, and ensure long-term performance.

We Specialize in Pump Reliability

Our experts have proven track record of designing solutions to improve pump reliability. Contact us to begin improving your reliability and improving mean time between failure